Automotive

Commercial Vehicles

NBC is major Supplier of Bearings and relevant solutions to all major Domestic Commercial vehicle manufacturers as well as to Global Commercial Vehicle giant like Daimler and allied companies. For Domestic applications, NBC Brand is preferred choice in after market as well as in servicing of vehicles. NBC offers standard, Specialized and Integrated Bearing solutions to following major applications:

Engine

- Alternator

- Idler Pulley

- Flywheel / Pilot Position

- Viscous Fan

Transmission

Propeller Shaft

Rear Centre Section and Front Centre Section (In case of 4X4)

- Regular

- Tandem

- Tridem

Front and Rear WheelEnd

Steering

NBC Commercial Vehicle Offerings :

- Power Dense Solutions for Transmission and Centre Section applications

- Low Friction / Fuel Efficient Solutions for

- overall driveline

- Integrated Solutions at Engine to reduce Assembly time and part inventory.

- Unitized Bearing solutions for Wheel End applications to improve Efficiency and reduce assembly weight. Improve Service intervals.

- Preset hub / integrated solutions for Wheel End applications, To reduce assembly time and improve service intervals.

- Customized Bearing sizes to meet Requirements.

Major Bearing Application Areas

Typical Truck Engine with 6 Cyliders

Bearings Are Required In Critical Applications Of:

- Alternator (FEAD)

- Flywheel / Pilot Position

- Idler Pulley (FEAD)

- Viscous Fan

Major Challenges Involved:

- High Speed and Continuous loading for Alternator and Pulley application.

- High Operating Temperatures at FEAD

- Variable Loading and very high operating Temperature for Viscous Fan application.

- For integrated solution, optimization of weight is another challenge.

- Effective sealing FEAD and Viscous fan application.

- Contaminated and severe application conditions for Flywheel position.

- High Durability and Warranty requirements.

- Low Torque for FEAD usages.

Solutions to Challenges

- Application Specific Design for FEAD, able to achieve RPM to tune of 15000. Special focus on Bearing Cage, Internal Geometry and Sealing etc.

- Sealing Configuration optimization for Low torque and contaminated environment.

- Stabilization Heat Treatment for high temperature application.

- Advanced Heat Treatment for meeting durability and Warranty targets.

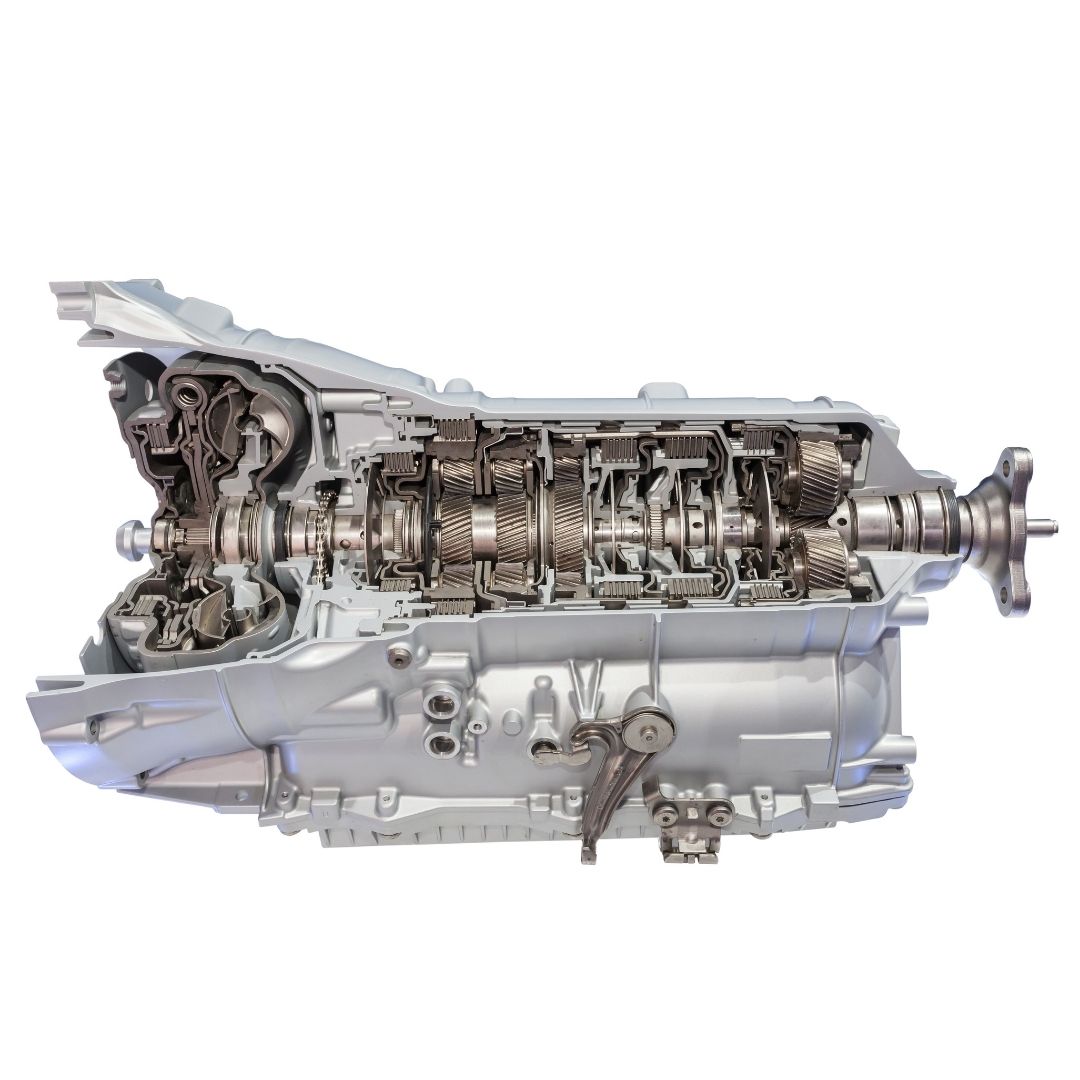

Typical Truck Transmission

Major Challenges Involved

- Very high Axial and Radial Loading

- Low Friction

- Contaminated Environment

- High Operating Temperature

- Compact Envelop

- High Durability and Warranty Target

- High Stiffness

Solution to Challenges

- Extra Capacity Bearing in Same Envelop with modification of geometry

- Special heat treatment for high temperature

- Power dense solution for high load application.

- Special heat treatment for compact size bearings

- Low Friction by modifying geometry

- Special heat Treatment for Contaminated environment

- Special Designed bearings for high stiffness application

+View Products

+Download Brochure

Rear / Front Centre Section

Major Challenges Involved

- Very high Axial and Radial Loading

- Low Friction

- Contaminated Environment

- High Operating Temperature

- Compact Envelop

- High Durability and Warranty Target

- High Stiffness

Solution to Challenges

- Extra Capacity Bearing in Same Envelop with modification of geometry

- Power dense solution for high load application

- Low Friction by modifying geometry

- Special Designed bearings for high stiffness application

- Special heat treatment for high temperature

- Special heat treatment for compact size bearings

- Special heat Treatment for Contaminated environment

Front And Rear Axle

Tractor implements are key add-ons to the tractor to make it multifunctional.

NBC offers bearings for various agricultural implements such as Rotary tiller, Power harrow, Power cutters, loader, Transplanter, Baler etc..

Major Challenges Involved

- High Tonnage Capacity

- Low Friction

- Contaminated Environment

- Compact Assembly

- Overload usage in applications

- High Durability and Warranty Target

- Reduced Weight

- Integrated solutions

Solution to Challenges

- Extra Capacity Bearing in Same Envelop with modification of geometry

- Power Dense Solutions for high tonnage application

- Unitized Bearing Solution for compact assembly and ease of service

- Integrated solution (Preset Hub) for ease of assembly and reduced inventory

- Optimized design and treatment for high durability and warranty target

Tractor implements are key add-ons to the tractor to make it multifunctional.

NBC offers bearings for various agricultural implements such as Rotary tiller, Power harrow, Power cutters, loader, Transplanter, Baler etc..

Major Challenges involved:

- Highly Contaminated operating Conditions

- Moderate to high temperature

- Good Durability and Warranty life

- Misalignment

- Low to moderate loading

Solution to Challenges

- Special sealing to meet demanding contaminated conditions

- 4 Seal configuration for contaminated operating conditions

- Optimized Geometry to take care of Misalignment

- Internal Design, Special heat treatment for enhanced durability and warranty life

Quick Finder Link

Latest Articles Updated Daily

Insight And Trends

Follow our latest news and thoughts which focuses exclusively on insight, industry trends, tip news headlines.

Why Manufacturing Excellence Is the Backbone of Global Industrial Growth: NBC’s Perspective

IntroductionIndustrial growth across the world is built on one fundamental capability—the ability to manufacture reliable, precise, and high-performance components. From automotive systems and heavy machinery

An Integral Facet of Operational Excellence: Aircraft & Aerospace Engineered Bearings

In the aerospace industry, every component matters. Whether it’s a commercial jet, a military aircraft, or a space-bound system, precision and reliability are non-negotiable. Among

Innovative Bearing Designs: Reshaping the Future

Innovative bearing designs are redefining modern engineering. As industries move toward higher performance and increased efficiency, advanced bearing technologies are emerging as critical enablers. From

Request more information

Leadership quotes