Failure Prevention in Large Diameter Bearings: NBC’s Approach to Reliability and Longevity

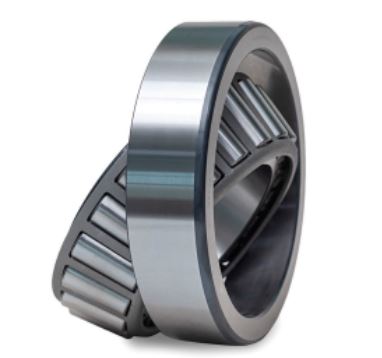

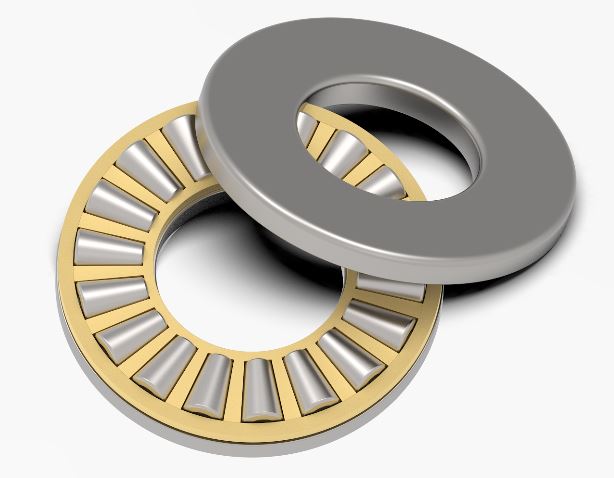

IntroductionLarge Diameter Bearings play a vital role in industries that operate with heavy loads, extreme forces, and demanding cycles. Sectors such as mining, steel, cement,