Innovating Industrial Efficiency With Nano Moly Coating

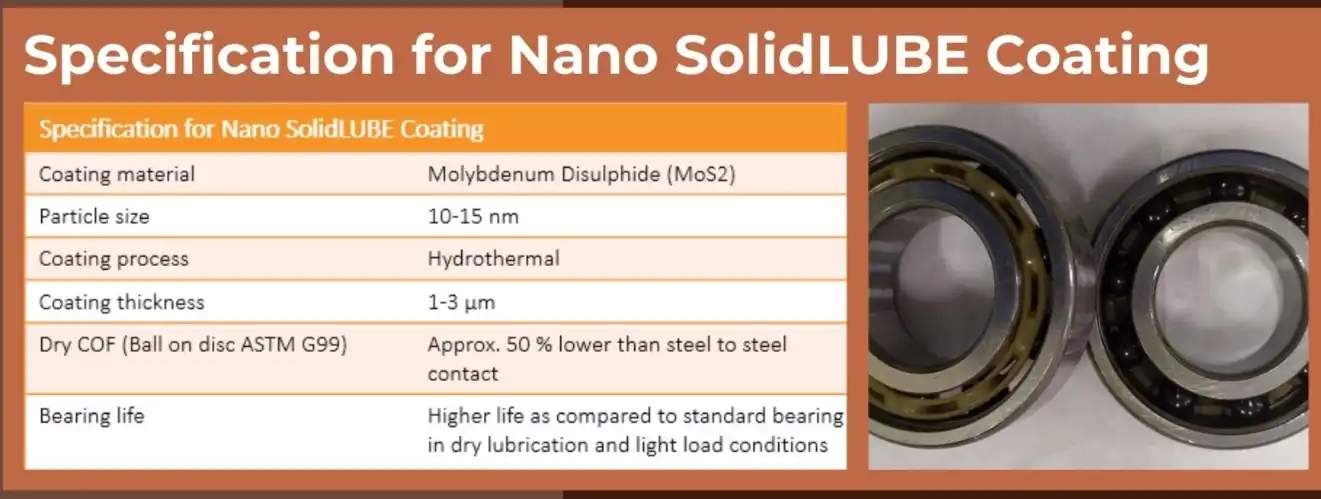

Nano SolidLUBE MoS2, derived from Molybdenum Disulfide, stands at the forefront of lubrication technology, offering unparalleled efficiency and durability in industrial applications. This revolutionary coating, composed of nano-sized MoS2 particles, forms a solid film on surfaces, reducing friction and wear while enhancing performance and longevity.

Importance of Lubrication in Industrial Applications

Lubrication is the lifeblood of machinery, ensuring smooth operation and preventing premature wear and tear. In industrial settings, where heavy loads, high speeds, and extreme conditions are commonplace, effective lubrication is paramount for maintaining equipment efficiency and reliability.

Nano SolidLUBE MoS2 coating addresses these challenges by providing a solid lubricating film that withstands harsh environments and extends maintenance intervals.

Key Benefits of Nano SolidLUBE (MoS2) Coating

The adoption of Nano SolidLUBE MoS2 coating offers a multitude of benefits which can be clubbed under three broad categories.

- Firstly, its solid film lubrication reduces friction and wear, resulting in smoother operation and extended component lifespan.

- Secondly, the nano-sized MoS2 particles penetrate surface irregularities, providing superior boundary lubrication and preventing metal-to-metal contact.

- Finally, Nano SolidLUBE MoS2 coating exhibits excellent adhesion to various substrates, ensuring long-lasting performance in diverse applications.

Applications of MoS2 Across Industries

The versatility of Nano SolidLUBE MoS2 coating makes it indispensable across a wide range of industries. From automotive and aerospace to manufacturing and marine, MoS2 coating finds applications in gears, bearings, shafts, and other critical components. Its ability to withstand extreme temperatures, pressures, and loads makes it ideal for demanding environments where traditional lubrication methods fall short.

Maintenance and Longevity of MoS2

One of the standout features of Nano SolidLUBE MoS2 coating is its maintenance efficiency and longevity. Unlike traditional lubricants that require frequent reapplication, MoS2 coating forms a durable solid film that remains intact even under harsh operating conditions. This reduces the need for regular maintenance, minimizes downtime, and lowers overall operational costs, making it a cost-effective solution for industrial applications.

Nano SolidLUBE (MoS2) Coating vs. Traditional Lubrication

When comparing Nano SolidLUBE MoS2 coating to traditional lubrication methods, the advantages are clear.

- While traditional lubricants may offer temporary relief from friction and wear, they often require frequent replenishment and are prone to breakdown under extreme conditions.

- In contrast, MoS2 coating provides long-lasting protection, reduces maintenance requirements, and enhances equipment performance, making it the preferred choice for industries seeking optimal efficiency and reliability.

FAQ's

Why is MoS2 special in the coating industry?

MoS2 is special in the coating industry due to its unique solid film lubrication properties, which reduce friction and wear while withstanding harsh operating conditions.

How do you coat molybdenum disulfide?

Molybdenum disulfide can be coated onto surfaces using various methods, including spraying, dipping, brushing, or electroplating, depending on the application requirements.

What is the purpose of moly coating?

The purpose of moly coating is to provide solid film lubrication, reducing friction and wear between surfaces in industrial applications, thereby enhancing efficiency and longevity.

How do you add moly to oil?

Moly can be added to oil-based lubricants through blending or mixing processes, ensuring uniform dispersion of moly particles throughout the lubricant for effective boundary lubrication.

Is Nano SolidLUBE (MoS2) Coating environmentally friendly?

Yes, Nano SolidLUBE (MoS2) coating is environmentally friendly as it reduces the need for frequent lubricant replenishment, minimizes waste generation, and prolongs equipment lifespan, leading to overall sustainability.

Is Nano SolidLUBE (MoS2) Coating cost-effective in the long run?

Yes, Nano SolidLUBE (MoS2) coating is cost-effective in the long run due to its extended maintenance intervals, reduced downtime, and enhanced equipment performance, resulting in overall savings for industrial operations.