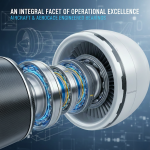

Nanotechnology, the manipulation of matter on an atomic and molecular scale, is revolutionizing various industries, and bearings are no exception. By harnessing the power of nanomaterials and nanoscale engineering, manufacturers are creating bearings with enhanced performance, durability, and efficiency. New-age bearings with nanostructured surfaces reduce friction and wear, resulting in smoother operation and longer lifespan in industrial machinery.

Friction's Foe: Nanolubricants to the Rescue

One of the most significant advancements facilitated by nanotechnology in bearing technology is the development of nanolubricants. These lubricants contain nanoparticles that reduce friction and wear between bearing surfaces, resulting in smoother operation and extended lifespan. For instance, nanodiamond-based lubricants have been shown to reduce friction by up to 55%, improving energy efficiency and reducing maintenance costs in wind turbines and automotive engines.

Beyond Lubrication: Nanocoatings for Superior Strength

In addition to nanolubricants, nanotechnology has paved the way for the development of advanced nanocoatings for bearings. These coatings, typically made from nanomaterials such as graphene or diamond-like carbon, provide exceptional protection against corrosion, abrasion, and wear. These new-age bearings come with nanocoatings that offer superior resistance to harsh operating conditions, prolonging the lifespan of machinery in industries such as aerospace and manufacturing.

The Future is Nano: A Glimpse into Tomorrow's Bearings

As we look ahead, the future of bearing technology lies in nanotechnology. Researchers and engineers continue to explore new avenues for enhancing bearing performance through nanoscale innovations. For example, MIT researchers are developing self-healing bearings embedded with nanoparticles that repair surface damage and extend maintenance intervals, reducing downtime and improving reliability in critical applications.

FAQ's

What is nanotechnology's role in improving bearings?

Nanotechnology enhances bearings by enabling the development of nanolubricants, nanocoatings, and nanomaterials with superior properties, resulting in bearings with enhanced performance, durability, and efficiency.

What are the advantages of nanostructured materials in bearings?

Nanostructured materials offer advantages such as increased hardness, strength, and wear resistance, as well as reduced friction and improved load-bearing capacity, leading to bearings with extended service life and enhanced reliability.

How do nanoparticles enhance lubrication in bearings?

Nanoparticles in lubricants reduce friction and wear by forming a protective layer between bearing surfaces, filling in microscopic imperfections, and preventing metal-to-metal contact, resulting in smoother operation and extended lifespan for bearings.

How does nanotechnology impact the future of bearing technology?

Nanotechnology opens up new possibilities for the development of advanced bearing technologies, including self-healing bearings, smart bearings with embedded sensors, and bearings with tailored properties for specific applications, driving innovation and efficiency in the industry.

Are bearings with nanotechnology more expensive?

While bearings with nanotechnology may have a higher initial cost due to the advanced materials and manufacturing processes involved, they often offer superior performance, durability, and longevity, making them a cost-effective investment in the long run.