Plummer block bearings, also known as pillow block bearings, are robust bearing units designed to support rotating shafts in various industrial applications. Here’s a breakdown of some of the key features of plummer block bearings:

- Support Structure: Plummer block bearings consist of a housing (block) and a bearing insert, which are typically made of cast iron or steel. The housing provides a stable platform for mounting the bearing insert.

- Versatile Design: These bearings are versatile and adaptable to different shaft diameters and mounting configurations, making them suitable for a wide range of applications.

- Sealing Options: Plummer block bearings may incorporate various sealing arrangements to protect the bearing from contaminants and retain lubrication, ensuring long-term reliability.

- Temperature Resistance: They are designed to withstand high temperatures and harsh operating conditions, making them suitable for use in demanding environments.

Basic Design and Components

The structure of a plummer block bearing consists of several components, including:

- Housing: The housing provides support and protection for the bearing insert. It is typically made of cast iron or steel and may feature mounting holes for easy installation.

- Bearing Insert: This component contains the rolling elements (balls or rollers) and the inner race, which is mounted onto the rotating shaft. The bearing insert is designed to fit snugly inside the housing and is secured in place with set screws or locking collars.

- Seals or End Covers: These components help prevent contamination and retain lubrication within the bearing assembly, enhancing its longevity and performance.

- Grease Fitting: Some plummer block bearings feature a grease fitting for easy lubrication, ensuring smooth operation and minimal maintenance requirements.

Applications of Plummer Block Bearings

Plummer block bearings find widespread use in various industries and applications, including:

- Conveyor Systems: Plummer block bearings are commonly used to support conveyor rollers, providing reliable and efficient material handling in industries such as manufacturing, distribution, and logistics.

- Agricultural Equipment: In agricultural machinery such as tractors, combines, and harvesters, plummer block bearings are used to support rotating shafts in components like pulleys, sprockets, and drive systems.

- Industrial Fans: These bearings are employed in industrial fan assemblies to support the fan shaft and facilitate smooth rotation, ensuring efficient air movement in ventilation and cooling systems.

Advantages and Benefits of Plummer Block Bearings

- Easy Installation: Plummer block bearings are designed for straightforward installation and maintenance, reducing downtime and labor costs.

- Versatility: They can accommodate various shaft diameters and mounting configurations, offering flexibility in design and application.

- Durable Construction: With robust housing materials and sealing arrangements, plummer block bearings exhibit excellent durability and resistance to environmental factors.

- Cost-Effective: These bearings provide reliable performance and long service life, offering excellent value for money in industrial applications.

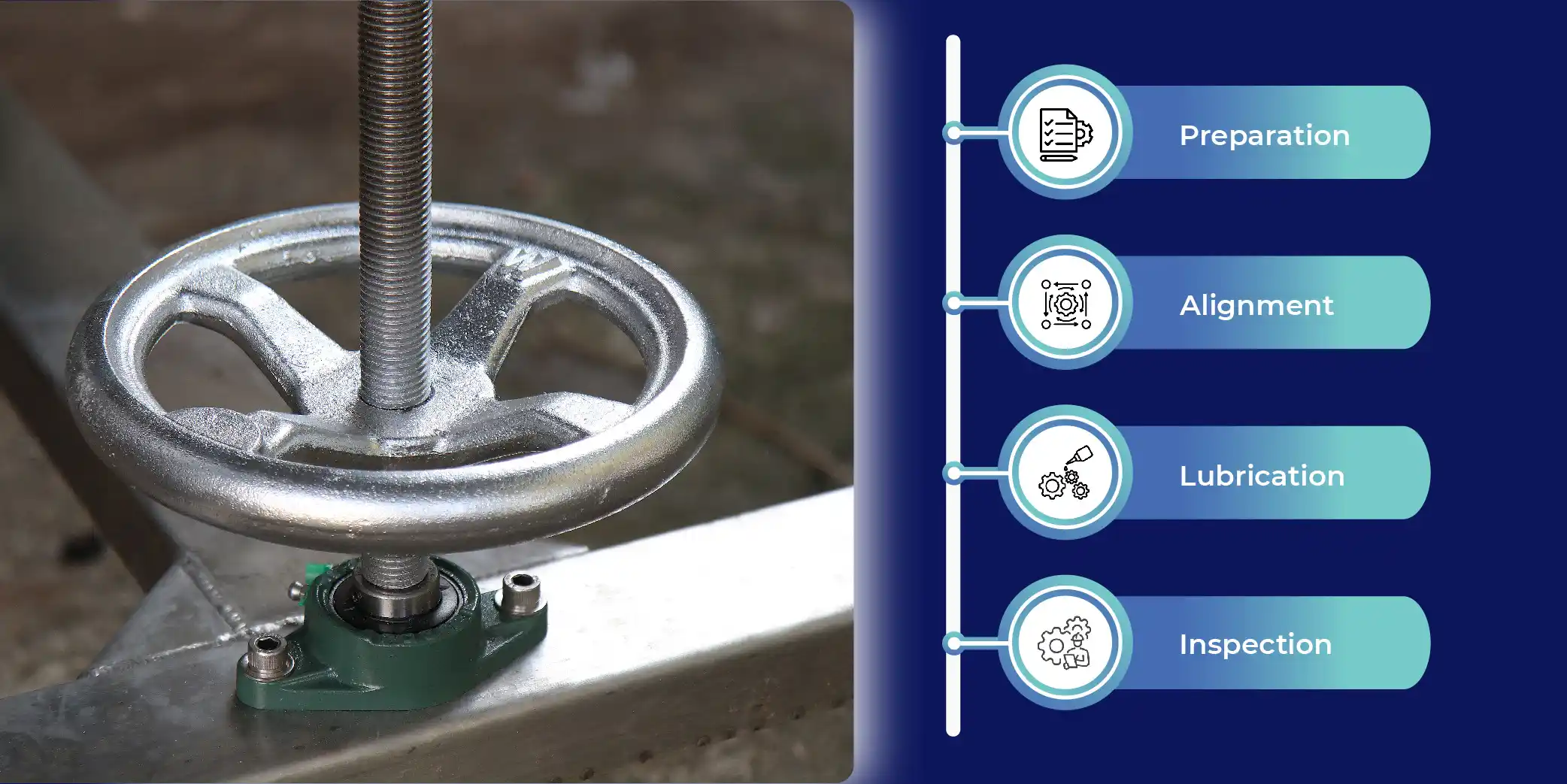

Installation and Maintenance Guidelines

Proper installation and maintenance practices are essential for ensuring optimal performance and longevity of plummer block bearings. Some best practices that can be followed are:

- Preparation: Ensure the housing and shaft are clean and free of debris before installation.

- Alignment: Properly align the bearing housing and shaft to prevent misalignment, which can lead to premature wear and failure.

- Lubrication: Apply the appropriate amount of lubricant to the bearing insert according to manufacturer recommendations. Regular lubrication intervals should be maintained to prevent dry running and excessive friction.

- Inspection: Periodically inspect the bearing assembly for signs of wear, damage, or contamination. Replace worn components and replenish lubrication as needed to maintain optimal performance.

In conclusion, plummer block bearings are versatile and reliable components widely used in industrial applications for supporting rotating shafts. Their robust construction, ease of installation, and low maintenance requirements make them indispensable in conveyor systems, agricultural equipment, and industrial fans. By following proper installation and maintenance guidelines, engineers and maintenance personnel can maximize the performance and longevity of plummer block bearings in various applications.

FAQ's

What bearings are used in plummer blocks?

Plummer block bearings typically use ball bearings or roller bearings, depending on the specific application requirements.

What is the difference between plummer and pillow block bearings?

The terms “plummer block bearings” and “pillow block bearings” are often used interchangeably to refer to the same type of bearing unit, which consists of a housing and a bearing insert.

Where is a plummer block used?

Plummer block bearings are used in a wide range of applications, including conveyor systems, agricultural equipment, industrial fans, and more.

Which bearing is used in SN 513 plummer block?

The SN 513 plummer block typically uses a ball bearing or roller bearing insert, depending on the specific requirements of the application.

What size are plummer blocks?

Plummer block bearings are available in various sizes and configurations to accommodate different shaft diameters and mounting arrangements.

How many types of plummer blocks are there?

Plummer block bearings come in various types and configurations, including split plummer blocks, solid plummer blocks, flanged units, and more. Each type is designed to meet specific application requirements and mounting considerations.