PRODUCTS

Railway Bearings

The railway system is the lifeline of the nation. NBC Bearings has been partnering with the Indian Railways since 1952. It’s a symbol of efficiency, reliability, and mass transportation. Railway bearings are specialised components designed to facilitate the movement of trains and ensure their safety and efficiency. These bearings come in various types and serve critical roles within the railway system, including supporting the wheels, driving gears, and main electric motors.

Bearings Used in Railway

Roller Bearing And Axle Box

Traction Motor Bearings

Spherical Roller Bearings

Cartridge Tapered Roller Bearings

Traction Motor Suspension Unit (MSU) Bearings

Insulated Traction Motor Bearings

Features of Railway Bearings

- High load capacity: Because railway bearings help carry the immense weight of trains

- Low friction: The bearings ensure smooth and efficient movement, which in turn leads to reduced wear and tear on the railway infrastructure.

- Low maintenance costs: There is low downtime, and safety concerns as millions of lives depend on it.

Types of Railway Bearings

- Railway Journal Bearings: Journal bearings are one of the most common types of railway bearings that support the axle of the train’s wheels and allow them to rotate smoothly. These are lubricated with oil, for minimised friction and operational wear for increased service life. These are capable of absorbing shocks and carrying heavy loads.

- Railway Bearings for Driving Gears: Driving gears transmit power from the locomotive’s engine to the wheels using specialised bearings. These are tapered roller bearings that can handle both radial and axial loads and withstand high thrust forces while maintaining precise alignment.

- Railway Bearings for Main Electric Motors: Electric trains rely on powerful electric motors for propulsion. Deep groove ball bearings and cylindrical roller bearings are often chosen for these applications due to their high-speed capabilities and durability.

Benefits of Railway Bearings

- Load Support: Railway bearings can withstand extreme radial and axial loads, while providing crucial support to the weight of the train. This ensures the wheels and axles rotate smoothly even under heavy loads.

- Low Friction: Engineered to minimise friction between moving components, these ensure lower energy consumption, enhanced fuel efficiency and power consumption.

- Smooth Operation: Smooth and consistent wheel rotation, for a quieter and more comfortable ride for passengers. It also prolongs the lifespan of railway tracks and minimises maintenance requirements.

- Durability: Railway bearings are built to withstand harsh operating conditions, including vibrations, shocks, and temperature variations. This is crucial for passenger safety. A failure in a bearing can lead to derailments or accidents, making the robust design and quality control of these bearings a critical factor in railway safety.

- Maintenance Predictability: Regular inspection and maintenance of railway bearings can be planned and scheduled in advance.Condition monitoring and predictive maintenance helps identify potential issues early. Regular inspections help identify wear, damage, or lubrication issues early, preventing costly breakdowns and accidents. Maintenance procedures include cleaning, lubrication, and replacement of worn bearings. Additionally, advanced technologies like vibration analysis and temperature monitoring are employed to detect potential problems.

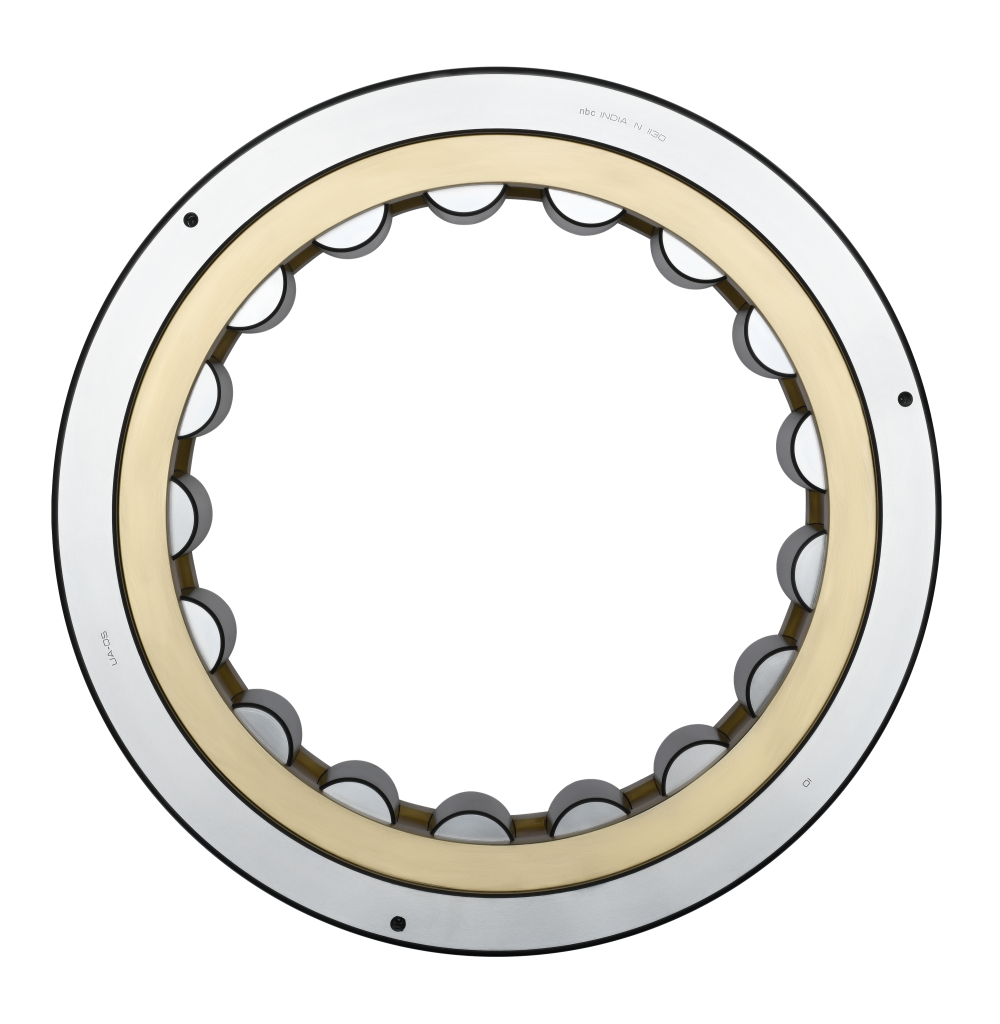

Roller Bearing and Axle Box

NBC has produced Axle Boxes for the railways since 1952. Over a million NBC bearings and axle boxes are in service with the Indian Railways. The development of completely indigenized axle boxes and bearings for the high speed Rajdhani Locomotive are the highlights of the design capabilities at NBC.

Cylindrical roller bearings are used mainly in locomotives (Diesel or Electric) for wheel application and traction motor application. These bearings are used with axle box housing and end fittings.

Traction Motor Bearings

Traction motors are a common means of powering a train, whether the energy required is carried on-board the train in the form of a diesel engine and its fuel or obtained from outside the train by connection with an external power supply carried by an overhead line

Spherical Roller Bearings

The manufacturing of spherical roller bearings was started in the year 1975 for fitment to broad gauge and meter gauge passenger coaches with designs, technology, machines and equipment procured from the collaborators.

Cartridge Tapered Roller Bearings

Cartridge taper roller bearings with technology from AmstedRail, USA, have the outstanding property of requiring no field lubrication. They are mainly used in various wagons like BOXN, BCN, BTPN, etc. designed by the Indian Railways. For fitment to these Wagons designed by the RDSO, NBC is the only manufacturer in India to indigenize these bearings under collaboration with BRENCO the largest manufacturer of these bearings in the world.

Traction motor suspension unit (MSU) Bearings

Traction motor suspension units (MSU) have been extensively used in locomotives to connect between frame‐mounted traction motors on and the wheels. Single row Tapered Roller Bearings are used as suspension bearings. These bearings are used with suspension tube housing and end fittings. For some special applications, cylindrical roller bearings are also used as suspension bearings (ABB Locomotive).

Benefits :- Increases reliability

- Reduces radial clearance and maintenance costs

- Low starting torque

- Grease lubrication (no oil levels to maintain)

Insulated Traction Motor Bearings

NBC has successfully developed Insulated Traction Motor bearings. First time in history of Indian Railways, NBC make indigenous insulated bearings were fitted in both electric & diesel locomotive applications.

Features:- Improves bearing life in electrical current passage

- Optimized coating with plasma spray process

- High insulation resistance

- High dimensional stability after coating

- Easy to mount

- Higher operational reliability

- Increased machine uptime

- Reduced overall operating costs

- Improves lubricant life

- Insulation over wide range of operating temperature

Bearings Used in Railway

FAQ's

Which bearing is used in railways?

Railway bearings used depend on the railway component and its intended application. These mainly include a combination of

- Journal bearings,

- Tapered roller bearings,

- Deep groove ball bearings, and

- Cylindrical roller bearings.

What kind of bearings are used on train wheels?

Train wheels are typically supported by journal bearings. This is because journal bearings specifically are engineered to handle heavy loads and provide smooth rotation. To ensure maximised output, these bearings are often lubricated with oil to reduce friction and wear.

Which bearing is used in railway axle boxes?

Railway axle boxes also use primarily journal bearings. These bearings play a crucial role in supporting the axle and wheel-set of the locomotive, ensuring their smooth and reliable operation.

Quick Finder Link

Latest Articles Updated Daily

Insight And Trends

Follow our latest news and thoughts which focuses exclusively on insight,industry trends, tip news headlines.

Why Manufacturing Excellence Is the Backbone of Global Industrial Growth: NBC’s Perspective

IntroductionIndustrial growth across the world is built on one fundamental capability—the ability to manufacture reliable, precise, and high-performance components. From automotive systems and heavy machinery

Read more

An Integral Facet of Operational Excellence: Aircraft & Aerospace Engineered Bearings

In the aerospace industry, every component matters. Whether it’s a commercial jet, a military aircraft, or a space-bound system, precision and reliability are non-negotiable. Among

Read more

Innovative Bearing Designs: Reshaping the Future

Innovative bearing designs are redefining modern engineering. As industries move toward higher performance and increased efficiency, advanced bearing technologies are emerging as critical enablers. From

Read more

Request more information

Client's Testimonials