30215

Tapered Roller Bearings

Tapered roller bearings are a fundamental component of many mechanical systems. This roller-element bearing is designed with precision and craftsmanship which efficiently helps transmit radial and axial loads.

Overview

Technical Specification

Download PDF

Overview

| Dimensions | |

|---|---|

| Bore Diameter | 75 mm |

| Outside Diameter | 130 mm |

| Width (Outer Ring) | 25 mm |

| Performance | |

|---|---|

| Fatigue Load Limit | 22 KN |

| Dynamic Load Rating | 156 KN |

| Static Load Rating | 175 KN |

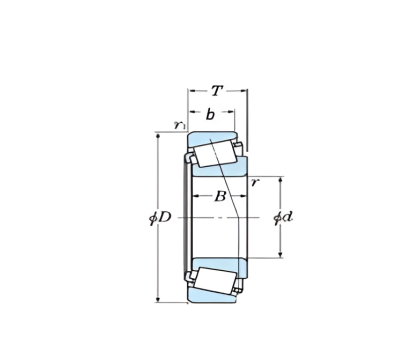

Technical Specification

| Boundary Dimensions | ||

|---|---|---|

| d | 75 | Bore Diameter |

| D | 130 | Outside Diameter |

| B | 25 | Width (Outer Ring) |

| b | 22 mm | Chamfer on Inner Ring |

| T | 27.25 mm | Chamfer on Inner Ring |

| r1 | 2.5 mm | Chamfer on Inner Ring |

| r | 2.5 | Chamfer on Inner Ring |

| Dynamic Load Rating | ||

|---|---|---|

| Cr(KN) | 156 | Dynamic |

| Cor(KN) | 175 | Static |

| Cr(Kgf) | 15870 | Dynamic |

| Cor(Kgf) | 17839 | Static |

| Calculations | ||

|---|---|---|

| e | 0.44 | Limiting Value |

| y2 | 1.38 | Calculation Factor |

| y0 | 0.76 | Calculation Factor |

| Mass | ||

|---|---|---|

| mass | 1.41 | kg |

Download PDF

| File | Actions |

|---|---|

| Tapered Roller Bearings |

Features:-

- Optimized Load Distribution: Helps reduce stress and prolong service life.

- High Radial and Axial Load Capacity: The bearings handle both radial and axial loads simultaneously, making them suitable for a robust performance.

- Precision Engineering: Leads to low friction, reduced wear, improved efficiency and durability.

- Reduced Maintenance Costs: Minimizes downtime and maintenance expenses, making this a cost-effective solution for businesses.

- Versatility: These work from automotive transmissions to heavy machinery, with a large range of applications. Temperature

- Resistance: Being a heavy load machinery component, it is engineered to be dependable in challenging environments. Also this way it saves energy too.

Applications:

- Automotive

- Aerospace

- Industrial Machinery in Mining, Construction & Steel Mills

- Railways

- Wind Turbines

- Oil and Gas and many more…

Why Choose Us:

- Uncompromising quality while ensuring consistent quality and reliability.

- Extensive experience of understanding customers’ needs and providing expert guidance.

- Customer support offering technical assistance, custom solutions, and prompt responses to inquiries.

- Competitive Pricing for flexible cost-effective solutions that deliver superior performance.

- Wide network ensuring high-quality tapered roller bearings are accessible across the world.

Choosing NBC Bearings means choosing reliability, quality, and support, making us the preferred partner for all your bearing needs.

Market Segments

Bearing Categories

Tapered Roller Bearings | Single Row Tapered Roller Bearings | Double Row Tapered Roller Bearings | Four Row Tapered Roller Bearings | Cylindrical Roller Bearings | Single Row Cylindrical Roller Bearings | Double Row Cylindrical Roller Bearings | Four Row Cylindrical Roller Bearings | Cylindrical Thrust Roller Bearings | Full Complement Cylindrical Roller Bearings | Spherical Roller Bearings