Understanding Frequent Problems in Industrial Machinery Applications

Machinery applications are often subject to a variety of problems, some of which are more frequent than others. Understanding the root cause of these problems can help to avoid them in the future:-

Paper Industry: Calandar Machine

-

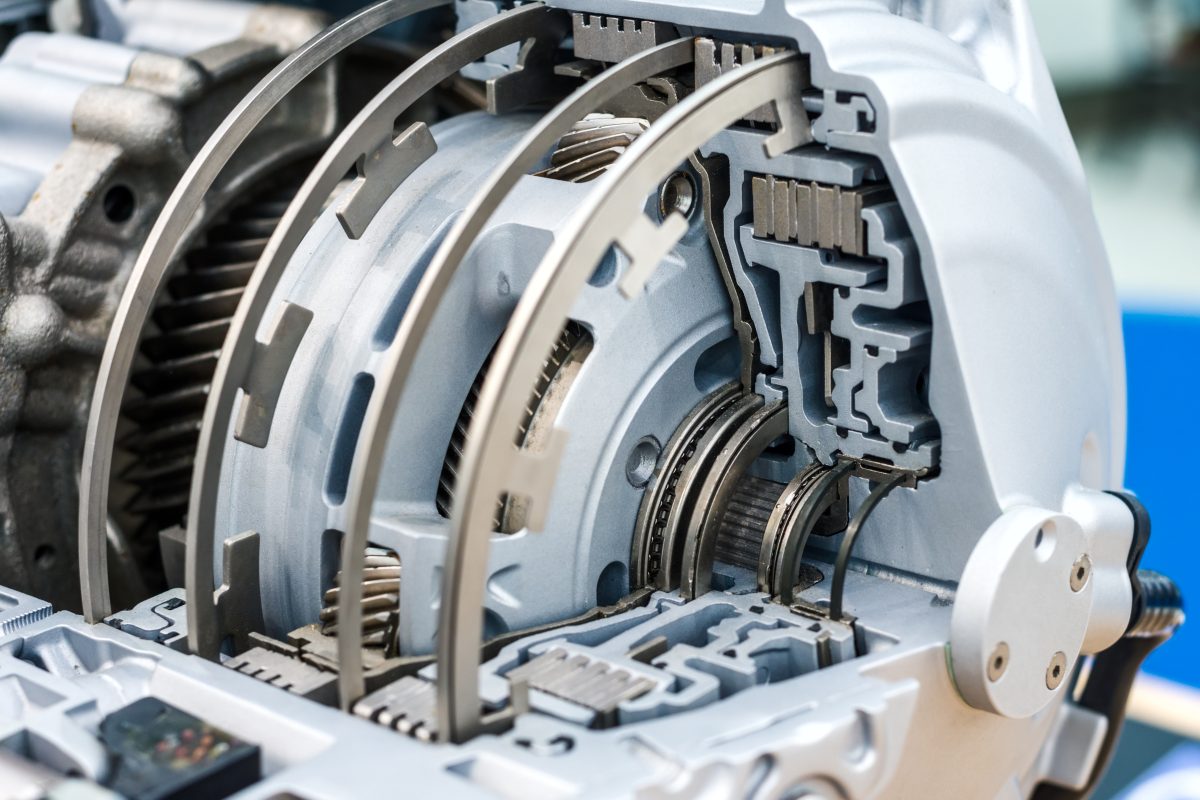

Hydraulic Applications: Pumps and Motors

-

Power Plant: Coal Pulveriser

Solutions: How Tungsten Carbide Carbon Coating Solve Challenges

WC/C Coating on rolling elements helps in withstanding wear and tear and other critical issues due to the nature of composition which is harder than metal-containing amorphous carbon coating. Here are some of the salient features of Tungsten Carbide Carbon Coating for bearings:-

- Thin Coating: Tungsten Carbide Carbon Coating features a very thin coating of 1-2 ?m.

- High Adhesion Strength: Adhesive strength is important because it allows bonding with surfaces securely which makes the bearing work as usual without resulting in breakdown due to angular misalignments.

- High Hardness: It helps in better surface contact between the components and increase the service life of bearings without wear and tear thus helping machinery components to work well.