In the intricate world of engineering, where precision and reliability are paramount, the dynamics of fits and tolerances play a crucial role in determining the performance and longevity of bearings. Understanding the principles behind fits and tolerances is essential for engineers and manufacturers striving to achieve optimal bearing functionality.

Understanding Fits and Tolerances

Fits and tolerances refer to the degree of interference or clearance between mating parts within a mechanical assembly. A proper fit ensures that components are securely aligned and function smoothly while allowing for necessary movement and thermal expansion. Tolerances define the acceptable limits of variation in dimensions, ensuring that parts meet specified requirements without compromising functionality or performance.

Importance of Fits and Tolerances in Bearing Performance

The proper selection and application of fits and tolerances are critical for achieving optimal bearing performance. A precise fit ensures that bearings operate within their designated clearance range, minimizing friction, wear, and the risk of premature failure.

Controlling fits and tolerances in bearing systems can significantly impact their performance and reliability by addressing several key factors:

- Reduced Vibration: Properly controlled fits and tolerances help maintain alignment between mating components, minimizing the risk of misalignment-induced vibration. When bearings are securely seated within their housing or mounted onto shafts with the appropriate fit, they experience smoother rotation and reduced oscillations. This reduction in vibration enhances the overall stability of the bearing system, leading to improved performance and longevity.

- Noise Reduction: Excessive clearance or interference between mating parts can result in unwanted noise generation within the bearing system. By optimizing fits and tolerances, engineers can minimize the amount of movement and friction between components, thereby reducing noise levels during operation. Tighter fits, in particular, help dampen vibrations and prevent components from rattling or vibrating against each other, resulting in quieter operation.

- Temperature Management: Properly controlled fits and tolerances also play a crucial role in managing temperature fluctuations within the bearing system. When components fit together with the correct clearances, they allow for proper thermal expansion and contraction during operation. This prevents binding or excessive heat buildup, which can lead to premature wear and failure. By maintaining optimal operating temperatures, engineers can enhance the reliability and efficiency of the bearing system.

- Proper Assembly: Achieving the correct fit during assembly is paramount to the performance of bearings. Proper alignment and installation techniques ensure that bearings are securely seated and aligned with mating components, preventing misalignment and uneven loading. Additionally, attention to detail during assembly helps minimize the risk of damage to bearing surfaces and extends their service life.

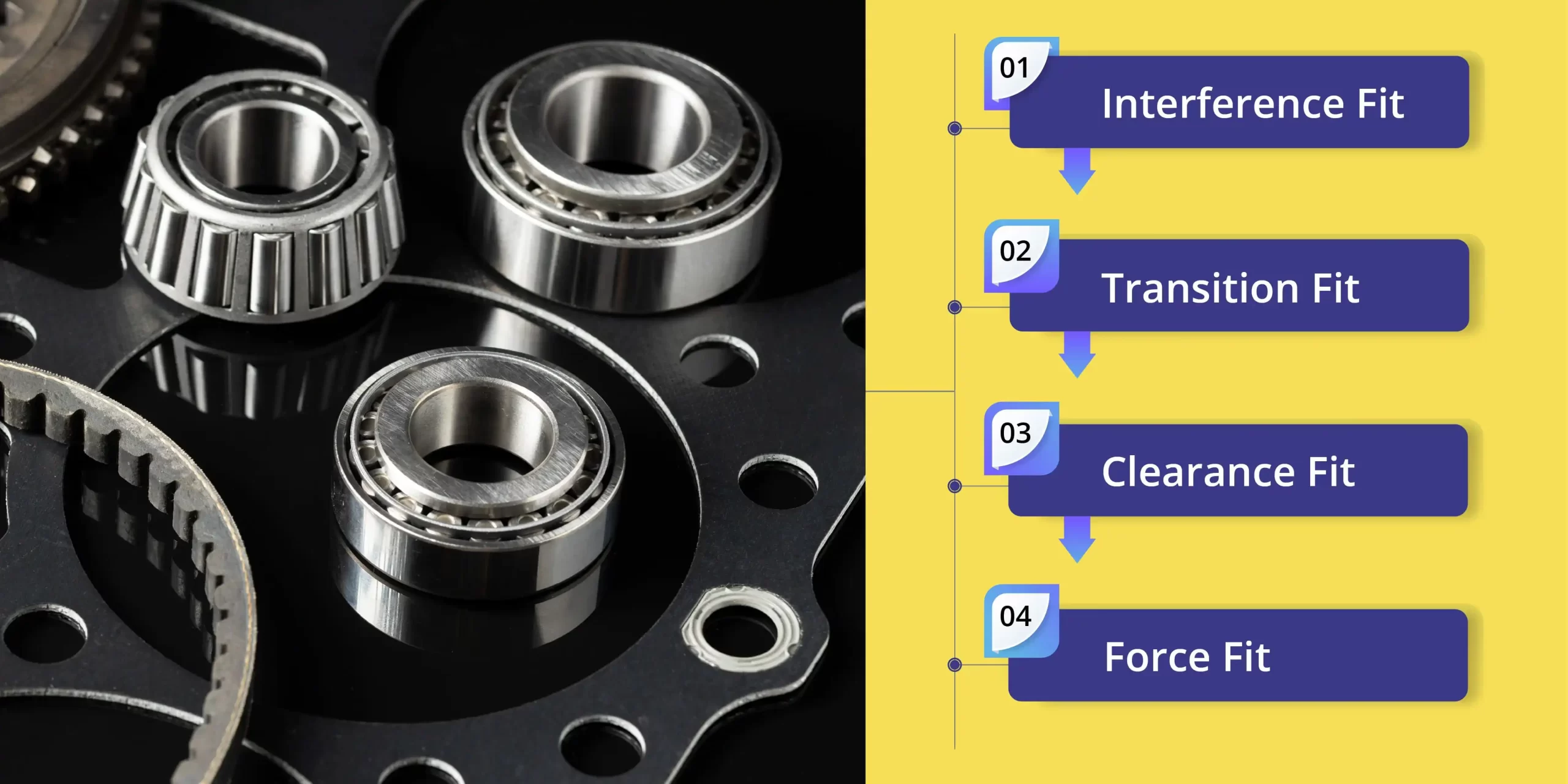

How Many Types of Fits are There?

Several types of fits are commonly used in bearing applications, including:

- Interference Fit: Where the shaft diameter is larger than the bearing bore diameter, creating a tight press fit.

- Transition Fit: Where the shaft diameter falls within the tolerance range of the bearing bore diameter, allowing for both clearance and interference.

- Clearance Fit: Where the shaft diameter is smaller than the bearing bore diameter, providing a loose fit with clearance for movement.

- Force Fit: Where the shaft is forcibly pressed into the bearing bore, creating a tight interference fit.

Selection of Fits and Tolerances in Bearing Applications

The selection of fits and tolerances in bearing applications depends on factors such as load requirements, operating conditions, material properties, and desired clearance levels. Engineers must carefully evaluate these factors and choose fits and tolerances that balance the need for precision, reliability, and ease of assembly.

FAQ's

What are the fits used in bearings?

Fits commonly used in bearings include

- interference fits,

- transition fits,

- clearance fits, and

- force fits

Each offers unique benefits and considerations depending on the application requirements.

What is bearing fitting?

Bearing fitting refers to the process of selecting and applying the appropriate fits and tolerances to ensure optimal performance and longevity of bearings in mechanical assemblies.

How should bearings fit?

Bearings should fit snugly within mating components, providing adequate clearance for smooth operation while maintaining sufficient interference to prevent slippage or misalignment.

What are the different types of fit?

The different types of fits include interference fits, transition fits, clearance fits, and force fits, each offering varying degrees of interference or clearance between mating parts.

What is the selection of fits?

The selection of fits involves choosing the appropriate combination of interference or clearance between mating parts to ensure optimal performance, reliability, and longevity of mechanical assemblies, such as bearings and shafts.