Bearings are one of the crucial components which are used in automobile parts. From steering and transmission to wheels, the bearing is useful to support the operations at varying levels. Read this blog to know more about the Use of Bearings in the Automobile Industry.

The automobile industry is one of the largest industries that source bearings in huge numbers. As every part of machinery within a car, truck or bus requires bearings to support operations and function heavy duty parts, bearings are something that can’t be missed.

The axle, engine, motors, and steering are some of the integral parts that have bearings at a large scale to make them work to make them operate smoothly while reducing friction. As the need for new makes and models are surging, the requirements for manufacturing bearings for automobiles are also soaring up high. With the latest trends and innovations, the

bearing manufacturers are also revving up their bearing design to accommodate new-age solutions.

Use of Bearings in the Automobile Industry

As you may already know it is next to impossible for automobile parts to function without the use of bearings. Here are various points that can help you know why bearings are crucial for automobiles.

1. Bearings Help in “Reducing Friction”

The main objective of using bearings is to reduce the friction between contact points. As metal to metal contact can give rise to issues such as wear and tear or breakdown, the bearings make it possible for various parts to function altogether while ensuring a proper contact and loadbearing capacity.

2. Bearings Help in Guiding Movement of Automobile Parts

Bearings are used for the purpose to move and turning the components of automobile parts relatively in a certain direction. It can support and guide the parts such as the wheel or steering shaft to offer ease of movement without any complexity. That is exactly how it makes it possible for steering to move the wheel in the desired direction.

3. Bearings Support Load Bearing Capacity

The bearings are made in such a way that they can easily bear thrust, angular and radial loads.

Due to the design and manufacturing, the bearings are heavy-duty components that have the capacity to bear the maximum load as per various applications which may change from part to part. The type of bearing used here can also differ in such cases.

Major Automobile Parts that use Bearings

Here are various automobile parts that use different types of bearing to support the smooth functioning and operation of the vehicle:

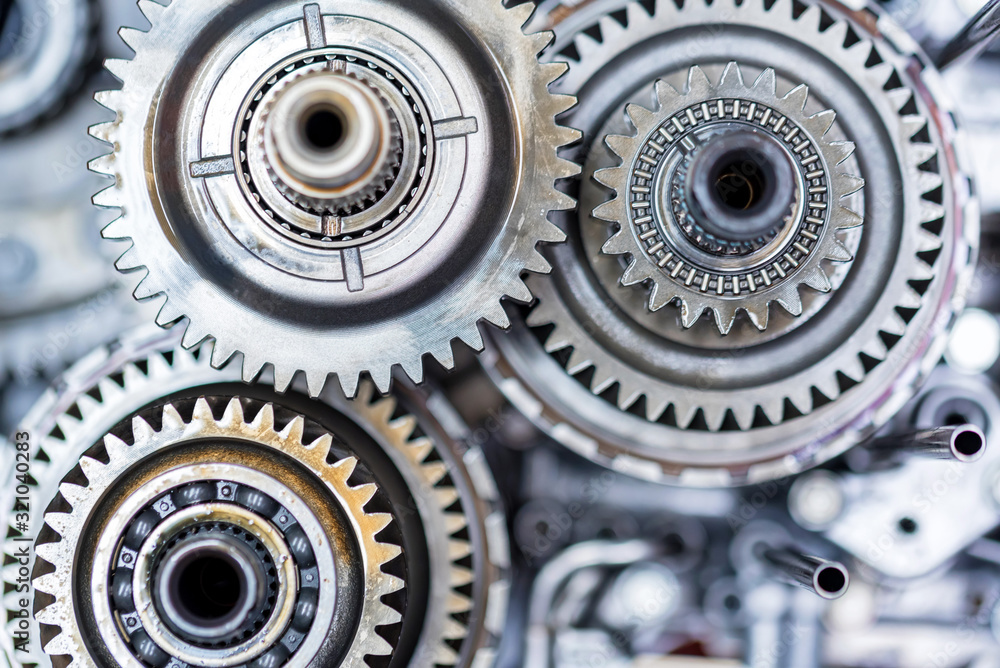

Transmission

The transmission is the most crucial device which converts the energy from the engine to adapt to the driving speed through gears. In such cases, the bearings are used to support the shaft to apply the desired force which controls the speed. The

deep groove ball bearing, cylindrical roller bearing and tapered roller bearing can be used in such applications as per different axial and radial loads

Wheels

The Ball Bearings can be used on wheels to support mobility. The bearings are fitted in the “cage” through which they evenly distribute the load of the vehicle. It also ensures the proper functioning of tire, wheel and hub assemblies.

Engine

The piston engine in automobiles uses various bearings to support the crankshaft and rotation of parts within the engine during the operation. In such cases, different types of bearings such as

tapered roller bearing, ball bearing, ball thrust bearings, etc are used.

Conclusion

The bearings come with exceptional capabilities to support varied operations within machinery. From handling load to working for longer hours without failure, bearings are crucial components that makeup machinery or systems. Since the automobile sector is growing and changing rapidly, the need to modify bearing design and performance have become more prevalent than in the past for bearing manufacturers.