In the realm of precision machinery, snap rings play a crucial role in securing components with simplicity and reliability. These small circular fasteners, also known as retaining rings or circlips, contribute significantly to maintaining the structural integrity and functionality of bearings. Unlike traditional fastening methods, snap rings simplify the assembly process while ensuring robust and dependable performance in precision machinery.

What is the Role of a Snap Ring in Bearings?

Securing Components: The primary function of snap rings in bearings is to secure essential components, such as outer races and shafts, in a specific position within the assembly. By preventing axial movement or shifting of parts, snap rings contribute significantly to the overall efficiency and longevity of bearings.

Preventing Axial Movement: One of the critical roles of snap rings is to prevent axial movement within the bearing assembly. This axial stability is vital for maintaining proper alignment and reducing wear over time. Without snap rings, the various components within a bearing might experience unintended shifts, leading to compromised performance and potential damage.

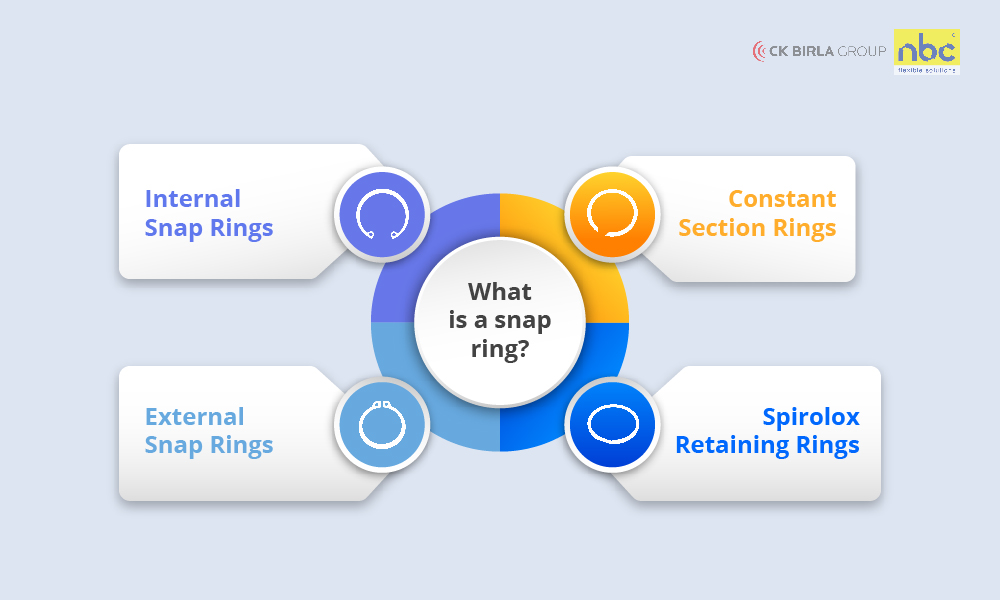

What Are the Types of Snap Rings?

Snap rings come in various types, each tailored to specific applications and assembly requirements.

- Internal Snap Rings: These rings fit inside a bore or housing, securing components from the inside. They are commonly used when the space constraints or design necessitate an internal fastening solution.

- External Snap Rings: Positioned on the outside of a shaft, external snap rings secure components externally. Their placement makes them readily accessible during assembly or disassembly processes.

- Constant Section Rings: Maintaining a consistent cross-sectional thickness, constant section rings offer uniform strength along their circumference. This design ensures a reliable and stable fastening solution.

- Spirolox Retaining Rings: Spirolox rings provide versatility in applications where dynamic movement and flexibility are required. Their spiral construction allows for easy installation and removal, making them suitable for a range of scenarios.

What Are the Benefits of Snap Rings?

- Axial Stability: The prevention of axial movement is a key contribution of snap rings. This axial stability ensures that the components remain aligned and do not experience unintended shifts during operation.

- Component Security:Snap rings play a crucial role in securing bearing components in place. This prevents dislocation or misalignment, ensuring that the bearing functions as intended under various operational conditions.

- Load Distribution: In addition to preventing axial movement, snap rings contribute to the even distribution of radial and axial loads. This distribution is essential for optimizing bearing performance and minimizing wear

- Simplified Assemblies: By eliminating the need for complex threading or additional fasteners, snap rings simplify the overall assembly, reducing the time and effort required for building the bearing system.

What Are the Different Snap Ring Materials and Designs?

- Materials: Commonly made from spring steel, for its durability and corrosion resistance, snap rings can withstand the rigors of various operating environments without compromising their structural integrity.

- Design Variations: Snap rings come in various design variations, each catering to specific needs and assembly requirements. However, the most common designs include internal, external, constant section, and Spirolox rings, each offering unique features for different scenarios.

- Coating Options: To enhance their protection against corrosion, some snap rings feature coatings such as zinc plating. These coatings provide an additional layer of defense, ensuring the long-term reliability of snap rings in challenging environmental conditions.

What Are the Applications of Snap Rings?

Snap rings find applications across various industries, where their unique design and functionality contribute to the efficiency and reliability of mechanical assemblies.

- Automotive Industry: Found with wheel bearings, transmissions, and various engine parts. Their role in preventing axial movement ensures the longevity and smooth operation of these essential automotive systems.

- Machinery and Equipment: Across diverse machinery and equipment, snap rings play a pivotal role in gears, pulleys, and rotating shafts.

- Aerospace: When lightweight and secure fastening are paramount, snap rings find applications in critical aircraft components. Their ability to maintain axial stability makes them crucial for ensuring the safety and efficiency of aerospace systems.

Snap rings, with their versatility and diverse designs, continue to be indispensable components in the realm of bearings. Whether ensuring the smooth operation of automotive components, contributing to the efficiency of machinery, or playing a vital role in aerospace applications, snap rings exemplify the significance of small yet powerful elements in the intricate world of mechanical assemblies.

FAQ's

What is a Snap Ring in a Transmission?

In a transmission, a snap ring acts as a retaining component which secures various transmission components preventing unintended movement during operation.

What is Another Name for a Snap Ring?

Snap rings are alternatively known as retaining rings or circlips. These names are often used interchangeably, referring to the same type of fastening component.

What Are Snap Rings Classified?

Snap rings are classified into internal and external types based on their placement in a bore or on a shaft. The classification helps in identifying their specific application within a mechanical assembly.

Are Snap Rings Internal or External?

Snap rings can be either internal or external, depending on their placement within a mechanical assembly. Internal snap rings fit inside a bore or housing, while external snap rings are positioned on the outside of a shaft.