AUTOMOTIVE

Passenger Cars

NBC is a trusted bearing solutions provider and preferred partner to many globally known Passenger Car OEM’s. With the advent of electrification and high efficiency requirements the market landscape for Pas Cars is rapidly changing. NBC’s wide offerings of bearing solutions have helped in making it a major bearing supplier for both Domestic and Global consumers.

NBC Passenger Car solutions –

- Power Dense Solutions

- “More Life” Solutions – Bearing with special heat treatment for fatigue life enhancement

- Improved bearing profiles for optimized performance in extreme conditions

- Maintenance free solutions – Oil Impregnated Bearing Solutions

- Improved design features for bearings to reduce noise and vibration

- Low torque solutions for higher efficiency

- Improved seals to reduce system torque during operation

- Wheel end application- integrated and customized solutions

- Needle roller bearings

Download Passenger Cars Catalogue

Major Bearing Application Areas

Cut section of 4 cylinder Engine

The Critical Application Areas of Bearing in Engine –

- Belt Tensioner Pulleys

- Cam Shaft

- Connecting rod

- Mass Balance shaft, as applicable

The Critical Application Requirements of Bearings –

- Contaminated operating conditions

- Contaminated operating conditions

- High Speeds

- Cyclic bearing loads

- Higher Service life & reliability

NBC Engine Bearing Solutions:

Following Specialized features offers cater to application specific requirements:

- lower friction & NVH

- improved internal geometry

- special surface & heat treatment

- Improved sealing solution

These design features help in meeting these critical application requirements and help in achieving higher service life & reliability.

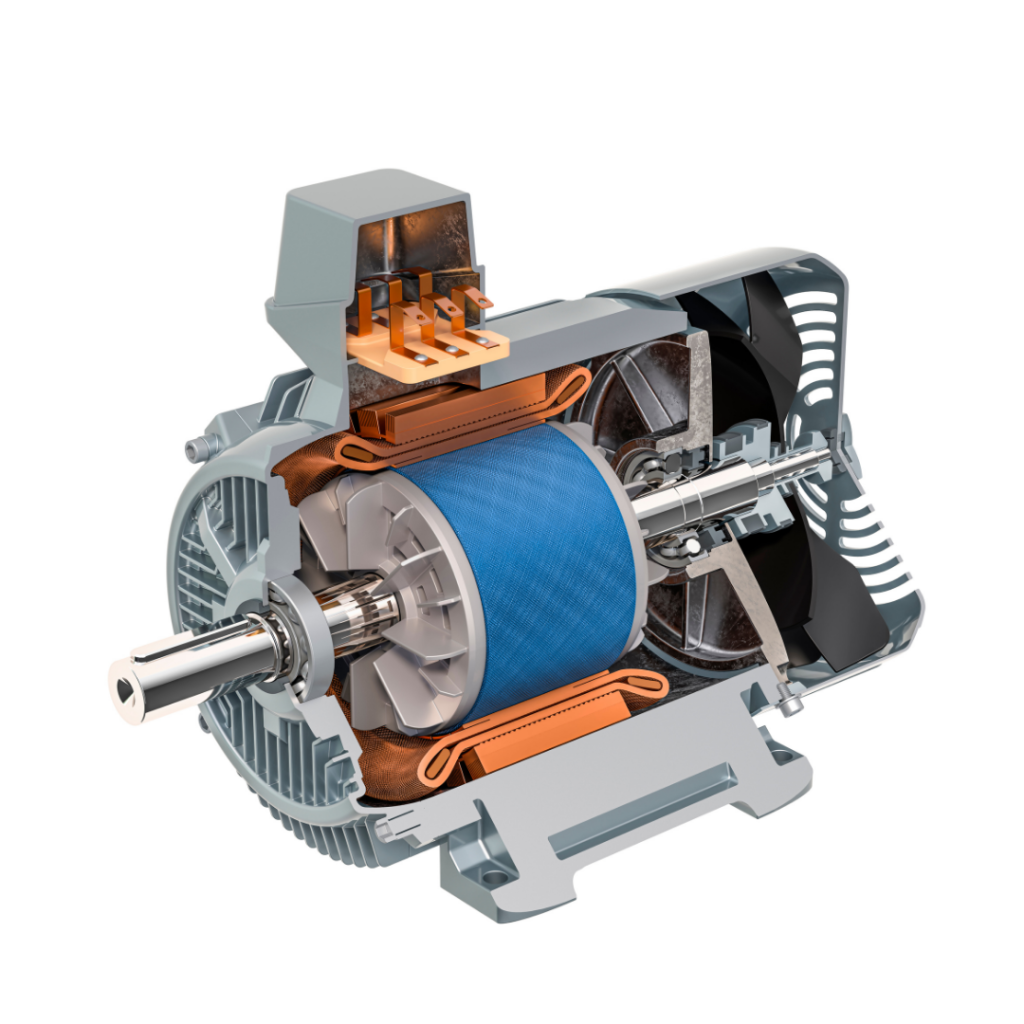

Cut section of E Motor

E motors are a specialized application, which are employed to generate power for Electric Transmissions. The critical application areas of bearing in Emotor is the Drive Shaft, which directly inputs power to the EV transmission/gearbox as shown in figure 2. The critical features of the application are:

- High Speeds

- Contaminated operating conditions

- Electric Insulation

- High Temperatures

- Smaller bearing envelope

- Mass Unbalance in drive shaft

NBC E Motor Bearing Solutions:

NBC’s customized bearing solutions cater to these niche application requirements:

- Lower friction & NVH

- Improved internal geometry

- Insulated grease options

- Special surface & heat treatment

- Improved sealing solutions

- Sensor Integrated Bearings

These design features help in meeting these critical application requirements and help in achieving higher service life & reliability.

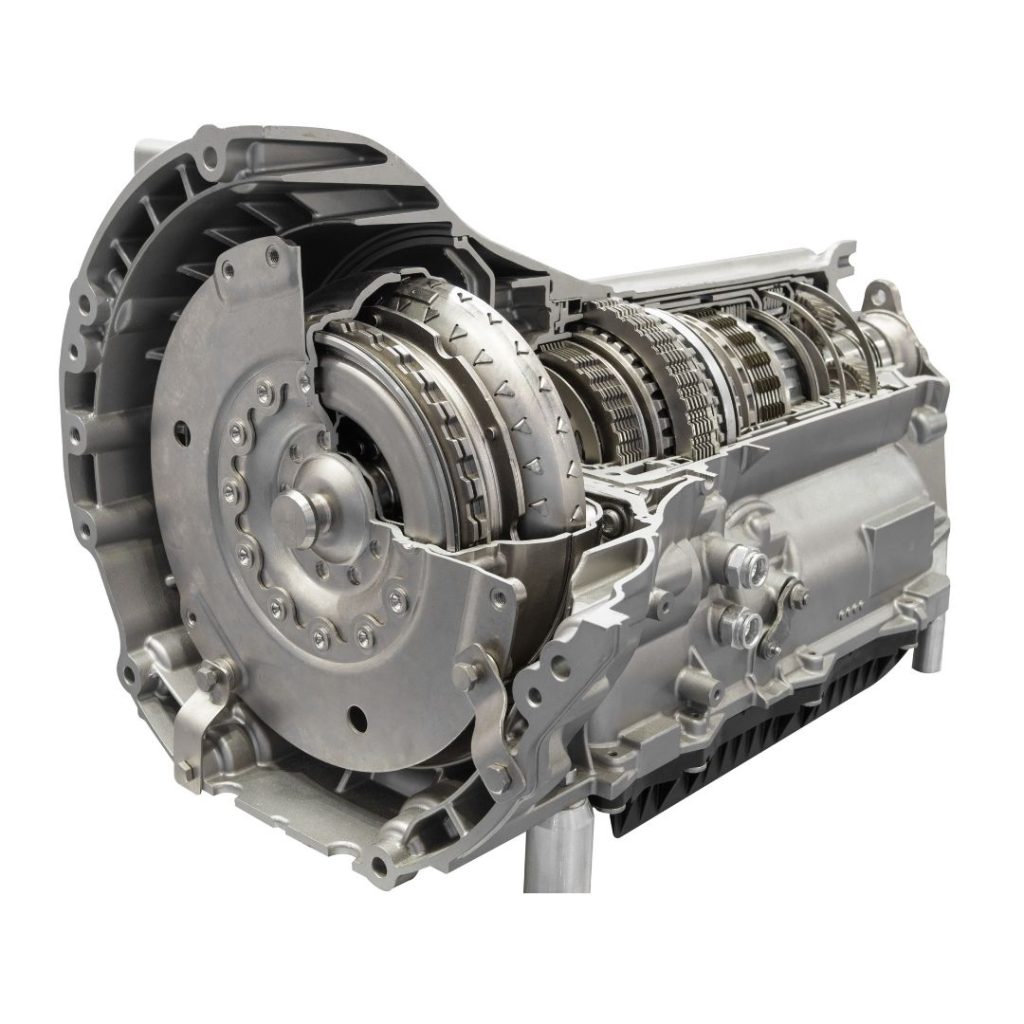

A Typical Manual Transmission

Transmissions help convert the power supplied by the Engine into usable toque. Based on the Pass Car type, various gearbox variants are used – Manual, Transaxle, Dual Clutch Transmission, E gearboxes, PHEV, Hybrids, etc. Following critical positions are present in these applications

- Input Shaft/Counter Shaft

- Differential Shaft

- Gear Blanks

The critical application requirements of bearings –

- High Speeds for E gearboxes

- Lesser Bearing Envelopes

- Contaminated operating conditions

- High Static Loading

- Shafts with high aspect ratios

- Higher component/system reliability

- Higher Service life

NBC Engine Bearing Solutions:

Following specialized features offers cater to application specific requirements:

- lower friction & NVH solutions

- Power dense solution

- improved internal geometry for higher static loading

- Low Torque solutions for improved efficiency

- special surface & heat treatment

- Improved sealing solution

Transmission bearings serve an important role in supporting the gearbox shaft systems operating under aggressive loading environment. Additionally, they also help in achieving the important milestones of minimum power loss, low noise & smooth continuous operation of vehicle.

Recently, NBC has also NRB solutions in its portfolio, which help us realise the important goal of providing a complete solution st for its Passenger Car customers.

Rear wheel end

The wheel end application demand for several essential features:

- Ease of mounting

- Maintenance free

- Contamination protection

- longer service life

- shock loading

- Integrated solutions

NBC offers various rolling solutions that cater to above requirements:

- Maintenance free solutions – Bearings that are greased for life

- OIBC – Oil Impregnated Bearing Cage for life team lubrication

- Next Gen integrated solutions (as shown in Figure 6) for ease of assembly

Quick Finder Link

Latest Articles Updated Daily

Insight And Trends

Follow our latest news and thoughts which focuses exclusively on insight, industry trends, tip news headlines.

Bearing Design Considerations: Pumps and Compressors

Bearings are what keeps machines synced and running for optimum performance. Which is why for uninterrupted operability, good bearings are a must for pumps and

Grinding And Honing for Quality Bearings

Grinding and honing are two vital processes in the manufacturing of bearings. These are the actions that ensure bearings get its precision, durability, and overall

Bearing Reliability in Heavy Machinery: Strategies, Challenges, and Best Practices for Max Performance

Industries work on the efficiency of machineries that perform a large chunk of the work in the factories. Responsible for facilitating smooth movement and reducing

Request more information

Leadership quotes