About Us

Sustainability

At NBC, sustainability is not an afterthought — it’s embedded in the way we engineer, manufacture, and serve. As the world moves toward a low-carbon future, we are committed to making meaningful contributions through cleaner processes, responsible sourcing, and transparent reporting.

From reducing emissions in our manufacturing operations to enabling our customers’ sustainability goals, we believe in taking ownership of our environmental impact — and acting on it.

Our Greenhouse Gas (GHG) Emission Metrics

To accurately assess our environmental impact, we collect activity data from various sources of GHG emissions across our operations. This data is aggregated at the corporate level to calculate NBC Bearings’ total carbon footprint. By benchmarking against industry standards, we identify areas for improvement and implement strategies to minimize our emissions.

Environmental Product Declarations (EPDs)

In our pursuit of sustainability, NBC Bearings has published Environmental Product Declarations (EPDs) for eight of our key bearing products. EPDs are standardized, third-party verified documents that transparently communicate the environmental impact of products throughout their life cycle—from raw material extraction to manufacturing, usage, and end-of-life disposal.

- EPD-IES-0017973:001 – TAPERED ROLLER BEARING :32309XA

- EPD-IES-0017974:001 – TAPERED ROLLER BEARING: 33022

- EPD-IES-0018019:001 – Cylindrical Roller Bearing: NUP310N

- EPD-IES-0018119:001 – Deep Groove Ball Bearing: 6010

- EPD-IES-0018138:001 – Unitized Taper Roller Bearing: N1764XAT2XLLX

- EPD-IES-0018154:001 – Double Row Angular Contact Bearing: AU0754-2LXL

- EPD-IES-0018184:001 – Cylindrical Roller Bearing: TS2NU2236

- EPD-IES-0018239:001 – Cartridge Tapered Roller Bearing: 6X11 Class ‘E’

Benefits of EPDs:

- Transparency: Provides verified data on the life-cycle environmental impacts of our bearings.

- Compliance: Aligns with international environmental standards such as ISO 14025 and EN 15804.

- Sustainable Procurement: Supports customers in making informed, eco-conscious purchasing decisions.

- Scope 3 Emissions Reporting: Assists clients in tracking and reporting indirect emissions associated with their supply chain.

Through these EPDs, we reaffirm our commitment to environmental stewardship and provide our stakeholders with the information needed to make sustainable choices.

Energy Management System

Paper Rationalization

Renewal Power Generation

Environment friendly products

Rain water harvesting and Water conservation

We have taken multiple initiatives to optimize fresh water usage and operate in prescribed limit. Also we have facility for rain water harvesting within factory premise. NBC Bearing’s rainwater harvesting exercise has ensured saving more than 6 million litres of water annually. We have reduced water consumption in our Jaipur Plant by 40% in last five years.

Environment friendly buildings

Waste management

Reusable/Returnable packaging

We have also begun to use returnable packaging solutions that helps in reduction of packaging waste. Our larger objective lies in reducing energy consumption and improving energy efficiency to support our overarching goal of lowering GHG emissions and Carbon Footprint.

With Happy Customers

Quick Finder Link

Latest Articles Updated Daily

Insight And Trends

Follow our latest news and thoughts which focuses exclusively on insight, industry trends, tip news headlines.

An Integral Facet of Operational Excellence: Aircraft & Aerospace Engineered Bearings

In the aerospace industry, every component matters. Whether it’s a commercial jet, a military aircraft, or a space-bound system, precision and reliability are non-negotiable. Among

Innovative Bearing Designs: Reshaping the Future

Innovative bearing designs are redefining modern engineering. As industries move toward higher performance and increased efficiency, advanced bearing technologies are emerging as critical enablers. From

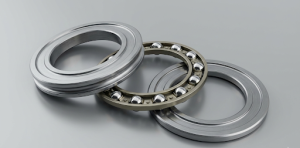

Thrust Roller Bearings: Reducing Friction and Supporting Axial Loads

Thrust roller bearings play a crucial role in a wide range of machines by reducing friction and supporting axial loads. Their design ensures smooth movement,

Request more information

Leadership quotes